Bronze

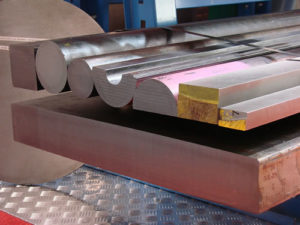

Bronze in Bars Produced by Continuous Casting

The production of bronze bars takes place by horizontal continuous casting process. This process consists of pouring the liquid bronze through a cooling shell placed horizontally at the bottom of the casting furnace.

This production method guarantees the absolute absence of defects within the bar. Bronze in bars can also be produced in continuous casting with a perforated section (tubes) due to the low melting temperature of this metal.

Centrifuged Bronze: medium and large bronze bushings are normally manufactured by centrifugation process.

This process consists of pouring liquid bronze into shells that rotate at a controlled speed and determine the outer diameter of the bronze bushings, while the inner diameter (thickness of the bronze bushings) is determined by the amount of bronze poured into the shell. Centrifuged bronze, precisely because of the compression effect due to centrifugation, is extremely compact and free of any impurities.

Bronze alloys and features:

The most commonly used Bronze is an alloy of Copper (Cu) and Tin (Sn), which proportionally increases the mechanical strength and corrosion resistance of this alloy, when added in varying percentages up to 12%.

Bronze is plastically workable and can therefore be extruded, rolled, forged, stamped and drawn. Obviously, in alloys with higher tin content, increasing hardness and mechanical strength will decrease malleability.

Another important type of bronze is obtained from the Copper (Cu) – Aluminium (Al) alloy, also called Aluminium Bronze or Cupro-Aluminium. The percentage of aluminium normally varies from 5% to 12% with the addition of Iron (Fe), Nickel (Ni) and Manganese (Mn).

The main characteristic of this bronze alloy is its remarkable mechanical strength and excellent corrosion resistance. As with tin bronzes, the percentage of aluminium is directly proportional to mechanical strength and inversely proportional to ductility, so up to 8% aluminium this bronze is still cold(?) deformable to obtain tubes, sheets and wires.

Beyond that, up to 10 % is hot(?) deformable and above 10 % the alloys obtained are with high wear resistance and very low ductility.

The characteristics of the other elements should also be mentioned, i.e. Iron (Fe), which increases the tensile strength by refining the crystalline grain, and Nikel (Ni), which improves corrosion resistance.

We have a well-stocked warehouse of bronze in bars of round, rectangular, square sections in the various standard alloys listed below:

Bronze G Cu Sn12 UNI 7013/2 (indicated by the previous UNI standard as B.14) available in:

- Continuous cast round bars from Ø15mm. to Ø300mm. in standard lengths of 3,000mm.

- Continuous cast round tubes from Øext.30/Øint.15mm. to Øext.250/Ø190mm. in standard lengths of 3’000mm.

- Centrifuged bushings up to Øext.2’000mm. and lengths according to request. Centrifuged bronze bushings are always supplied rough (by turning) on both outside and inside and cut to length.

- Rectangular bars with dimensions from ≠30 x 15mm. to ≠300 x 100mm. in standard lengths of 3’000mm.

- Square bars with dimensions from ≠20 x 20mm. to ≠ 100 x 100mm. in standard length of 3’000mm.

Bronze G Cu Sn5 Zn5 Pb5 UNI 7013/8 and Bronze G Cu Sn7 Zn4 Pb6 UNI 7013/7 (also called: Bronze 85.5.5 and Bronze Sn7)

This bronze is available in:

- Continuous cast round bars from Ø15mm. to Ø300mm. in standard lengths of 3,000mm.

- Continuous cast round tubes from Øext.30/Øint.15mm. to Øext.250/Ø190mm. in standard lengths of 3’000mm.

- Centrifuged bushings up to Øext.2000mm. and lengths according to request. Centrifuged bronze bushings are always supplied rough (by turning) on both outside and inside and cut to length.

- Rectangular bars with dimensions from ≠25 x 15mm. to ≠300 x 100mm. in standard lengths of 3’000mm.

- Square bars with dimensions from ≠20 x 20mm. to ≠100 x 100mm. in standard length of 3’000mm.

Aluminium Bronze Cu Al11 Fe4 Ni4 UNI 5275 (also called Aluminium Bronze; BRAL or XANTAL) available in:

- Continuous cast round bars from Ø15mm. to Ø300mm. in standard lengths of 3’000mm.

- Continuous cast round bars from Ø15mm. to Ø300mm. in standard length of 3’000mm.

- Continuous cast round tubes from Øext.30/Øint.15mm. to Øext.250/Ø190mm. in standard lengths of 3’000mm.

- Centrifuged bushings up to Øext.2’000mm. and lengths according to request. Centrifuged bronze bushings are always supplied rough (by turning) on both outside and inside and cut to length.

- Rectangular bars with dimensions from ≠20 x 10mm. to ≠300 x 100mm. in standard lengths of 3’000mm.

- Square bars with dimensions from ≠20 x 20mm. to ≠100 x 100mm. in standard length of 3’000mm.

Other types of bronze are also available on request, such as:

Lead Bronze, Nikel Bronze 25%, Phosphor Bronze, etc…

We can produce customised profiles in various sizes and formats.

All bronze bars can be supplied cut to size (see technical catalogue section ‘Services’).

All bronze sold by Commerciale Fond is produced by foundries with a certified “Quality System” in compliance with UNI EN ISO 9001-2008.