Bronzo

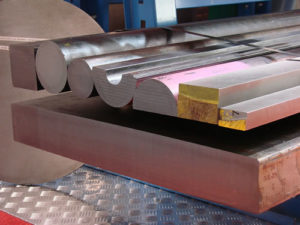

Bronzo in Barre prodotte mediante colata continua

La produzione del Bronzo in barre, avviene mediante processo di Colata Continua orizzontale. Questo processo consiste nel far uscire il bronzo liquido per gravità, attraverso una conchiglia di raffreddamento posta orizzontalmente, sul fondo del forno di colata. Questo metodo di produzione, garantisce assoluta assenza di difetti all’interno della barra. Il bronzo in barre può essere prodotto in colata continua anche con sezione forata (tubi) grazie alla bassa temperatura di fusione di questo metallo.

Bronzo Centrifugato: le boccole in bronzo di medie e grandi dimensioni, vengono normalmente realizzate mediante processo di centrifugazione. Questo processo consiste nel versare il bronzo liquido in conchiglie che ruotano a velocità controllata e che determinano il diametro esterno delle boccole in bronzo, mentre il diametro interno (spessore delle boccole in bronzo) viene determinato dalla quantità di bronzo versato nella conchiglia. Il bronzo centrifugato, proprio grazie all’effetto di compressione dovuto alla centrifugazione, è estremamente compatto ed esente da ogni tipo di impurità.

Leghe di Bronzo e caratteristiche:

Il Bronzo più comunemente utilizzato, è una lega di Rame (Cu) e Stagno (Sn), che aggiunto in percentuali variabili fino al 12%, aumenta in modo proporzionale la resistenza meccanica e la resistenza alla corrosione di questa lega. Il bronzo è lavorabile plasticamente e pertanto può essere estruso, laminato, forgiato, stampato e trafilato. Ovviamente nelle leghe con maggiori percentuali di stagno, aumentando la durezza e la resistenza meccanica, diminuirà la malleabilità.

Altra importante tipologia di bronzo, è quella ottenuta dalla lega Rame (Cu) – Alluminio (Al), detta anche Bronzo Alluminio o Cupralluminio. La percentuale di alluminio varia normalmente dal 5% al 12% con aggiunta anche di Ferro (Fe), Nikel (Ni) e Manganese (Mn). La principale caratteristica di questa lega di bronzo è la notevole resistenza meccanica e l’ottima resistenza alla corrosione. Come per i bronzi allo stagno, la percentuale di alluminio è direttamente proporzionale alla resistenza meccanica ed inversamente proporzionale alla duttilità, pertanto fino all’8% di alluminio questo bronzo è ancora deformabile a freddo per ottenere tubi, lastre e fili. Oltre, fino al 10% è deformabile a caldo e oltre il 10% si ottengono leghe ad alta resistenza all’usura con scarsissima duttilità. Nel merito di queste leghe, occorre ricordare anche le caratteristiche degli altri elementi presenti, ovvero il Ferro (Fe) che aumenta il carico di rottura affinando il grano cristallino, il Nikel (Ni) che migliora la resistenza alla corrosione.

Disponiamo di un fornito magazzino di bronzo in barre di sezioni tonde, rettangolari, quadrate nelle varie leghe standard sotto indicate:

Bronzo G Cu Sn12 UNI 7013/2 (indicato dalla precedente normativa UNI come B.14) disponibile in:

- Barre tonde in colata continua da Ø15mm. a Ø300mm. in lunghezza standard di 3’000mm.

- Tubi tondi in colata continua da Øext.30/Øint.15mm. a Øext.250/Ø190mm. in lunghezza standard di 3’000mm.

- Boccole centrifugate con dimensioni fino a Øext.2’000mm. e lunghezze secondo richiesta. Le boccole in bronzo centrifugato, vengono sempre fornite sgrossate (mediante tornitura) sia sull’esterno che sull’interno e tagliate a misura sulla lunghezza.

- Barre rettangolari con dimensioni da ≠30 x 15mm. a ≠300 x 100mm. in lunghezza standard di 3’000mm.

- Barre quadre con dimensioni da ≠20 x 20mm. a ≠ 100 x 100mm. in lunghezza standard di 3’000mm.

Bronzo G Cu Sn5 Zn5 Pb5 UNI 7013/8 e Bronzo G Cu Sn7 Zn4 Pb6 UNI 7013/7 (denominati anche: Bronzo 85.5.5.5 e Bronzo Sn7)

Questo bronzo è disponibile in:

- Barre tonde in colata continua da Ø15mm. a Ø300mm. in lunghezza standard di 3’000mm.

- Tubi tondi in colata continua da Øext.30/Øint.15mm. a Øext.250/Ø190mm. in lunghezza standard di 3’000mm.

- Boccole centrifugate con dimensioni fino a Øext.2000mm. e lunghezze secondo richiesta. Le boccole in bronzo centrifugato, vengono sempre fornite sgrossate (mediante tornitura) sia sull’esterno che sull’interno e tagliate a misura sulla lunghezza.

- Barre rettangolari con dimensioni da ≠25 x 15mm. a ≠300 x 100mm. in lunghezza standard di 3’000mm.

- Barre quadre con dimensioni da ≠20 x 20mm. a ≠100 x 100mm. in lunghezza standard di 3’000mm.

Bronzo Alluminio Cu Al11 Fe4 Ni4 UNI 5275 (detto anche Bronzo alluminio; BRAL o XANTAL) disponibile in:

- Barre tonde in colata continua da Ø15mm. a Ø300mm. in lunghezza standard di 3’000mm.

- Barre tonde in colata continua da Ø15mm. a Ø300mm. in lunghezza standard di 3’000mm.

- Tubi tondi in colata continua da Øext.30/Øint.15mm. a Øext.250/Ø190mm. in lunghezza standard di 3’000mm.

- Boccole centrifugate con dimensioni fino a Øext.2’000mm. e lunghezze secondo richiesta. Le boccole in bronzo centrifugato, vengono sempre fornite sgrossate (mediante tornitura) sia sull’esterno che sull’interno e tagliate a misura sulla lunghezza.

- Barre rettangolari con dimensioni da ≠20 x 10mm. a ≠300 x 100mm. in lunghezza standard di 3’000mm.

- Barre quadre con dimensioni da ≠20 x 20mm. a ≠100 x 100mm. in lunghezza standard di 3’000mm.

Su richiesta sono disponibili anche altre tipologie di bronzo quali ad esempio:

Bronzo al Piombo, Bronzo al Nikel 25%, Bronzo fosforoso, ecc…

Possiamo realizzare profili a disegno, di svariate dimensioni e formati.

Tutte le barre in Bronzo possono essere fornite tagliate a misura (vedere catalogo tecnico sezione “Servizi”)

Tutto il bronzo commercializzato da Commerciale Fond, viene prodotto da fonderie con “Sistema di Qualità” certificato conforme alla norma UNI EN ISO 9001-2008.