Alluminio

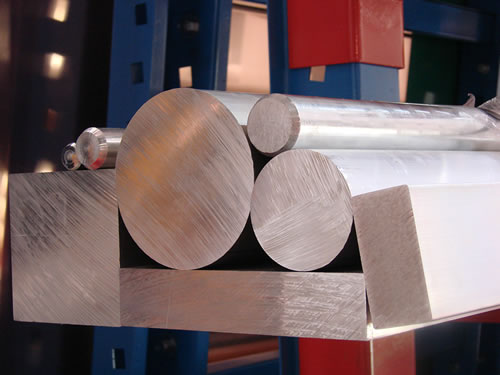

Alluminio in Barre Estruse o Trafilate e Lastre

La produzione dell’Alluminio in barre, avviene mediante processo di estrusione ovvero, per compressione di una billetta (alluminio in barre prodotto per colata continua verticale) riscaldata fino allo stato di rammollimento, ed estrusa attraverso una matrice in acciaio che conferisce al metallo la forma desiderata.

Dopo l’estrusione, se richiesto, la barra di alluminio estruso così ottenuta può essere sottoposta a processo di trafilatura. Questo processo eseguito “a freddo” consiste nel far passare la barra attraverso una matrice in acciaio di dimensioni calibrate, così da conferire alla sezione di Alluminio trafilato un profilo con tolleranza dimensionale molto ristrette (vedere relative tabelle all’interno del catalogo tecnico).

La produzione delle lamiere e lastre in alluminio avviene mediante processo di laminazione di placche fuse in colata continua verticale. La laminazione consiste nel trascinamento del materiale attraverso due rulli ad assi paralleli e controrotanti, lo spazio tra i due rulli (canale) determina lo spessore della lastra in alluminio o della lamiera.

Disponiamo di un fornito magazzino di barre, lastre, tubi e lamiere in alluminio nelle seguenti leghe:

- Alluminio “99,5” Lega 1050 disponibile in lamiere lisce di formato 1000×2000 + 1250×2500 + 1500×3000 con spessori da 0,5 a 10 mm – Stato fisico H 24

- Alluminio “99,5” Lega 1050 disponibile in lamiere mandorlate, di formato 1000×2000 + 1250×2500 + 1500×3000 con spessori da 2+M a 5+M mm – Stato fisico 0

- Alluminio “Avional 100” Lega 2017 disponibile in lastre laminate con spessori da 10 a 120mm, tagliate alla misura richiesta dal cliente. – Stato fisico T 4.

- Alluminio “11S” Leghe 2011, 2007 e 2030 disponibile in barre tonde, quadre, rettangolari. Estruse e trafilate con lunghezza mt.3 – Stato fisico T3 – T 8 – T 6

- Alluminio “Anticorodal 100” Lega 6082 disponibile in barre tonde, quadre, rettangolari, estruse con lunghezza da 3 e 6 metri – Stato fisico T6

- Lamiere e lastre laminate con spessori da 4 a 300 mm, tagliate alla misura richiesta dal cliente – Stato fisico T 651

- Alluminio “Anticorodal 63” Lega 6060 disponibile in barre tonde, quadre, rettangolari, tubi, angolari, canaline e profili speciali in genere, lunghezza standard 6 metri. – Stato fisico T 5 – T 6

- Alluminio “Peraluman” Lega 5083 disponibile in lastre laminate con spessori da 8 a 200mm. Stato fisico H 111.

- Alluminio “Peraluman” in blocchi fusi di spessore 600 x 1500 x 3’000mm. Stato fisico F; tagliato alla misura richiesta dal cliente.

- Alluminio “Peraluman” Lega 5083 disponibile in lastre laminate con spessori da 8 a 200mm. Stato fisico H 111, blocchi fusi di spessore 600 mm Stato fisico F ; tagliato alla misura richiesta dal cliente

- Alluminio “Peraluman” Lega 5754 disponibile in lastre laminate con spessori da 0,5 a 12 mm e in lamiere mandorlate, di formato 1000×2000 + 1250×2500 + 1500×3000 con spessori da 3+M a 5+M mm – Stato fisico H 111 – 114

- Alluminio “Ergal 55” Lega 7075 disponibile in barre tonde estruse e trafilate lunghezza mt. 3, in lastre laminate con spessori da 4 a 200 mm Stato fisico T 6, blocchi fusi di spessore 500mm. Stato fisico T 79; tagliato alla misura richiesta dal cliente

Possiamo realizzare profili estrusi a disegno, di qualunque dimensione e formato.

Tutte le barre o lastre in alluminio possono essere fornite tagliate a misura (vedere catalogo tecnico sezione “Servizi”)

Tutto l’alluminio commercializzato da Commerciale Fond, viene prodotto da fonderie con “Sistema di Qualità” certificato conforme alla norma UNI EN ISO 9001-2008.